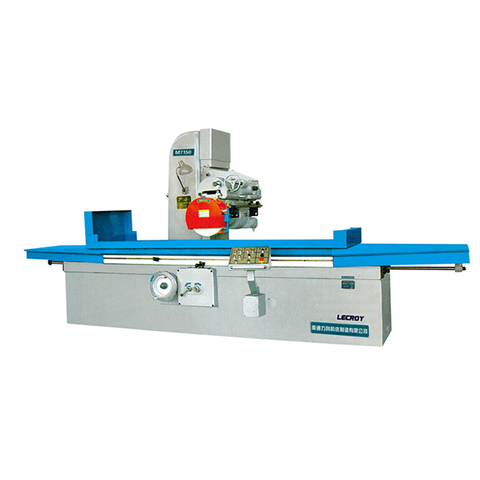

Description

All kind of working table size can meet different product range.

3-axis automatic movement with incremental downfeed and electronic auto-crossfeed.

AH- standard. Vertical: Manual Cross: Automatic motor( Intermittent )

Longitudinal: Hydraulic AHR Vertical: manual + rapid moving

Cross: Automatic motor( Intermittent ) Longitudinal: Hydraulic

AHD. Vertical:AC servo motor+ PLC control

Cross: Automatic motor(optinal: AC servo motor )

Longitudinal: Hydraulic

Precision hand scrapped turcite table and saddle ways for smooth and long lasting performance.

High column design with 450-600mm spindle center to table for extra clearance under the wheel.

Rapid elevation motor for quick and easy positioning of grinding head/wheel.

Centralized automatic one-shot lubrication system provides lubrication to all points.

Technical Parameters:

| Model | unit | SGA2050AH | SGA2550AH | SGA3063AH | SGA4080AH | SGA40100AH | ||

| SGA2050AHR | SGA2550AHR | SGA3063AHR | SGA4080AHR | SGA40100AHR | ||||

| SGA2050AHD | SGA2550AHD | SGA3063AHD | SGA4080AHD | SGA40100AHD | ||||

| Table Size (L× W) | mm | 460*200 | 540*250 | 630*300 | 800*400 | 800*400 | ||

| Max. load on working table | kg | 120 | 180 | 280 | 500 | 500 | ||

| Max movement of working table(L× W) | mm | 5000*230 | 560×280 | 650*320 | 900*450 | 900*450 | ||

| Distance from center of spindle to working table | mm | 450 | 450 | 510 | 600 | 600 | ||

| Wheel Size(OD*W*ID)) | mm | φ200×20×Φ31.75 | φ200×20×Φ31.75 | φ350×40×Ф127 | φ350×40×Φ127 | φ350×40×Φ127 | ||

| Wheel speed | 50HZ | r/min | 2850 | 2850 | 1450 | 1450 | 1450 | |

| 60HZ | 3440 | 3440 | 1680 | 1680 | 1680 | |||

| Longitudinal speed of working table | m/min | 3 -18 | 3 -20 | 8-25 | 7-25 | 7-25 | ||

| Cross feeding (front / back) on handwheel | Per revolution | mm | 2.5 | 2.5 | 4 | 4 | 4 | |

| Per graduation | mm | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 | ||

| Automatic feeding speed | intermittently | mm/min | 0.1 – 8 | |||||

| rapid continuously | mm/min | 690 | 690 | 690 | 990 | 990 | ||

| Vertical feeding (up / down) on handwheel | Per revolution | mm | 1.25 | 1.25 | 1.25 | 1.25 | 1.25 | |

| Per graduation | mm | 0.005 / 0.01 | 0.005 / 0.01 | 0.005 / 0.01 | 0.01 | 0.01 | ||

| Automatic feeding speed | intermittently | mm/ stroke | AH/AHR: n/a AHD: 0.005/0.01/0.02/0.03/0.04/0.05 | |||||

| rapid continuously | mm/min | AH: n/a AHR/AHD:460 | ||||||

| Spindle motor | kw | 1.5 | 2.2 | 4 | 5.5 | 5.5 | ||

| Driving motor ( up / down) | kw | AH: n/a AHD: 0.25kw AHR: servo motor 0.5kw | ||||||

| Driving motor ( front / back) | w | 40 | 120 | 180 | ||||

| Hydraulic motor | kw | 1.5 | 1.5 | 2.2 | 2.2 | 2.2 | ||

| Coolant pump motor | W | 40 | 125 | |||||

| Oil tank capacity | L | 80 | 80 | 80 | 80 | 120 | ||

| The parallelism of working surface to base level | mm | 0.005 /300mm ( optional: 0.003 /300mm) | ||||||

| Surface roughness | μm | Ra0.32 | Ra0.4 | |||||

| Weight ( N/G) | kg | 1400 / 1500 | 1600/1700 | 2200/2350 | 3200/3400 | 3800/4000 | ||

| Machine floor area ( L*W) | mm | 2050*1400 | 2300*1650 | 2900*2200 | 3600*2400 | 4400*2400 | ||

| Package size | mm | 1900x1700x1950 | 2000×1900×2000 | 2250×2100×2150 | 2800×2200×2200 | 2900*2250*2250 | ||

Standard Accessories

Grinding wheel

Wheel Flange

Wheel balancing base

Wheel balancing arbor

Elecro-magnetic chuck

Diamond table dresser base & tip

Leveling bolts & pads

Work light

Toolbox with tools

Optional Accessories

Digital Readout System

Fine pole electric chuck & control

Permanent chuck

Dust-suction coolant system

Overhead parallel dresser

Extra wheel flange