Contact us

- +86 13815922677 / +86-523-8549496

- +86-523-8549496

- joyce@arismachinery.com / joycechen2677@gmail.com

- No.999,Tianmu West Road,Jiangyan District,Taizhou,China

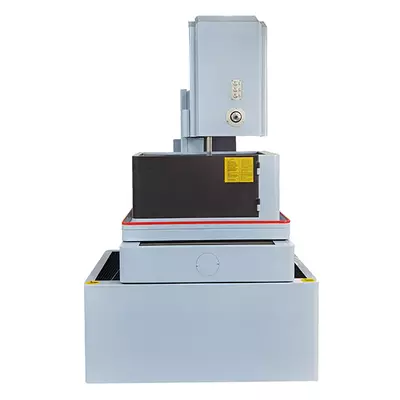

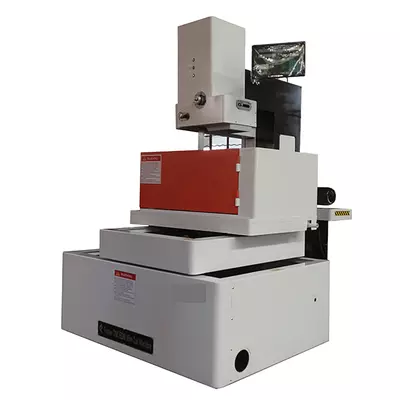

Multi-cut EDM wire cutting machine is an electric discharge wire cutting machine that uses spark discharge between an electrode and a workpiece to cut metal materials. It can cut in multiple directions, improving cutting efficiency and precision.

What are the advantages of multi-cut EDM wire cutting machine?

High precision: Due to the use of electric spark discharge cutting, very high precision can be achieved, and a cutting accuracy of 0.005mm can be achieved.

High efficiency: Can cut in multiple directions, thereby improving cutting efficiency and production efficiency.

High cutting quality: It can cut metal materials of various hardnesses without mechanical deformation, so the cutting quality can be guaranteed.

Can cut complex shapes: Since the multi-cut EDM wire cutting machine can cut in multiple directions, very complex shape cutting can be achieved.

What are the application fields of multi-cut EDM wire cutting machine?

multi-cut EDM wire cutting machine is widely used in mold manufacturing, aerospace, automobile manufacturing, electronic manufacturing, medical device manufacturing, and other fields.

What issues should be paid attention to in the maintenance of multi-cut EDM wire cutting machines?

The multi-cut EDM wire cutting machine requires regular cleaning and replacement of electrode wires, and it is also necessary to regularly check whether the various parts of the machine are functioning properly.

As a multi-cut EDM wire cutting machine manufacturer, we have the following unique advantages:

Technology leadership: We have advanced technology and a professional R&D team that can continuously introduce new products and continuously improve the performance and quality of our products.

Innovative design: We continue to carry out innovative designs to provide customers with more efficient, stable, and precise cutting solutions.

High-quality materials: We use high-quality materials and components to ensure our products have a longer service life and higher reliability.

Personalized customization: We can provide personalized customization services according to customer needs and requirements, and provide customers with the best solutions.

Professional services: We have a professional after-sales service team to provide customers with a full range of technical support and services to ensure the smooth progress of customers’ production operations.