Contact us

- +86 13815922677 / +86-523-8549496

- +86-523-8549496

- joyce@arismachinery.com / joycechen2677@gmail.com

- No.999,Tianmu West Road,Jiangyan District,Taizhou,China

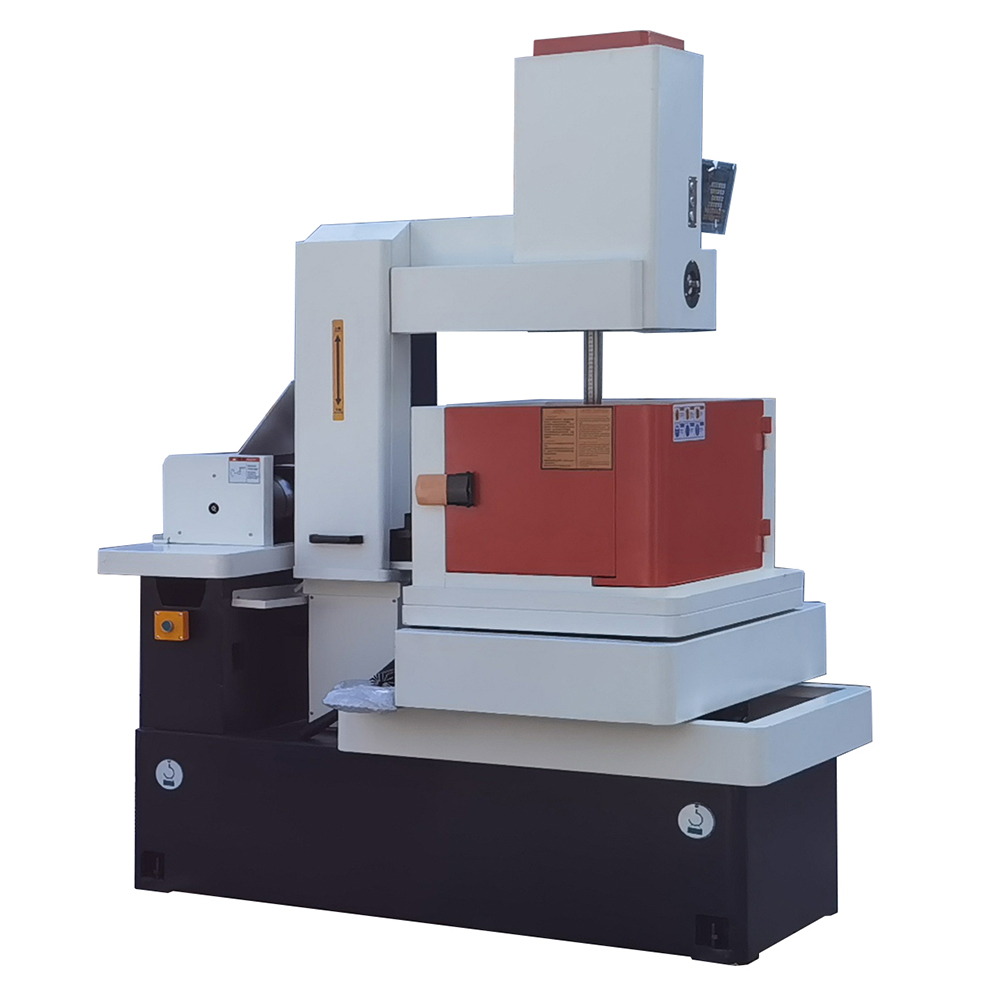

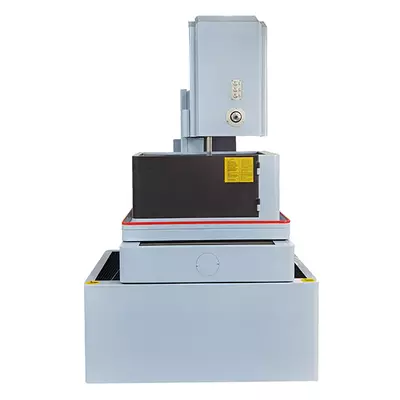

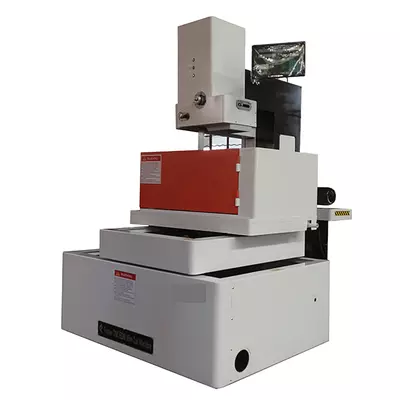

EDM wire cut machine is a kind of electric discharge wire cutting machine, also known as electric discharge wire cutting machine. It uses electric discharge technology to cut metal materials, by placing a thin wire electrode over the workpiece, and cutting the workpiece with electrical pulses. The machine can cut metal materials of various shapes, including carbide, steel, copper, aluminum, etc. It is widely used in mold manufacturing, precision machinery manufacturing, electronic component manufacturing and other fields in the manufacturing industry.

Machine structure of EDM wire cut machine:

The machine structure of EDM wire cut machine mainly includes machine tool, workbench, electrode and control system. The machine tool is the main part of the whole machine, used to support and fix the workbench and electrodes. The workbench is a platform for fixing workpieces, which can be moved in three dimensions for processing of various shapes. Electrodes are metal wires used for electrical discharge machining that can be controlled via electrode wires. The control system is the core part of the whole machine, which is used to control the movement of the electrode and the table, and to control the spark discharge between the electrode and the workpiece.

The technical characteristics of EDM wire cut machine mainly include the following aspects:

High processing precision: Due to the use of the principle of electric spark discharge for processing, high-precision processing can be realized, and the precision can reach 0.001mm.

Fast processing speed: Due to the use of the principle of electric spark discharge for processing, high-speed processing can be realized, and the processing speed can reach hundreds of millimeters per hour.

Wide range of applications: EDM wire cut machine can process workpieces of various shapes, including flat surfaces, curved surfaces, chamfers, holes, etc.

Wide range of processing materials: It can process various metal materials, including steel, copper, aluminum, titanium, etc.

Simple operation: The control system of EDM wire cut machine adopts digital control, which is easy to operate and can realize automatic processing.

EDM wire cut machine is a high-precision processing equipment, suitable for cutting and processing various metal materials, including hard alloy, high-speed steel, stainless steel, aluminum alloy, copper alloy, etc. It is widely used in mold manufacturing, precision machining, electronic component manufacturing, aerospace, automobile manufacturing, and other fields.

Specific application areas include:

Mold manufacturing: capable of cutting molds of various shapes with high precision, including plastic molds, die-casting molds, injection molds, etc.

Manufacturing of electronic components: It can process high-precision electronic components, including chips, circuit boards, wires, etc.

Precision machining: It can process precision parts of various shapes, including gears, bearings, threads, etc.

Aerospace: It can process high-precision aerospace parts, including engine parts, turbine blades, etc.

Automobile manufacturing: It can process various shapes of auto parts, including engine parts, gearbox parts, etc.

How to maintain EDM wire cut machine:

Regular Cleaning: After use, the machine surface and work area should be cleaned to prevent the accumulation of dust and dirt.

Lubrication: Regularly lubricate the various parts of the machine to ensure their smooth operation. Use an appropriate lubricant and follow the manufacturer’s recommendations.

Replace the filter element: replace the filter element of the machine regularly to ensure the normal operation of the machine. The filter element prevents dust and dirt from entering the machine.

Check the cords: Check the machine’s cords and plugs regularly to make sure they are not damaged or frayed. If any problems are found, they should be repaired or replaced immediately.

Check cutting wires: Check cutting wires regularly to make sure they are not damaged or frayed. If any problems are found, they should be replaced immediately.

Regular maintenance: Regular maintenance of the machine, including cleaning, lubricating, replacing filter elements and checking wires and cutting lines. Follow manufacturer’s recommendations and guidelines.

Maintenance during downtime: When the machine is down, the work area should be cleaned and all parts of the machine should be returned. This prevents dust and grime from accumulating and extends the life of the machine.

Periodic Inspection: Regularly inspect the various parts of the machine to make sure they are not damaged or worn. If any problems are found, they should be repaired or replaced immediately.