Contact us

- +86 13815922677 / +86-523-8549496

- +86-523-8549496

- joyce@arismachinery.com / joycechen2677@gmail.com

- No.999,Tianmu West Road,Jiangyan District,Taizhou,China

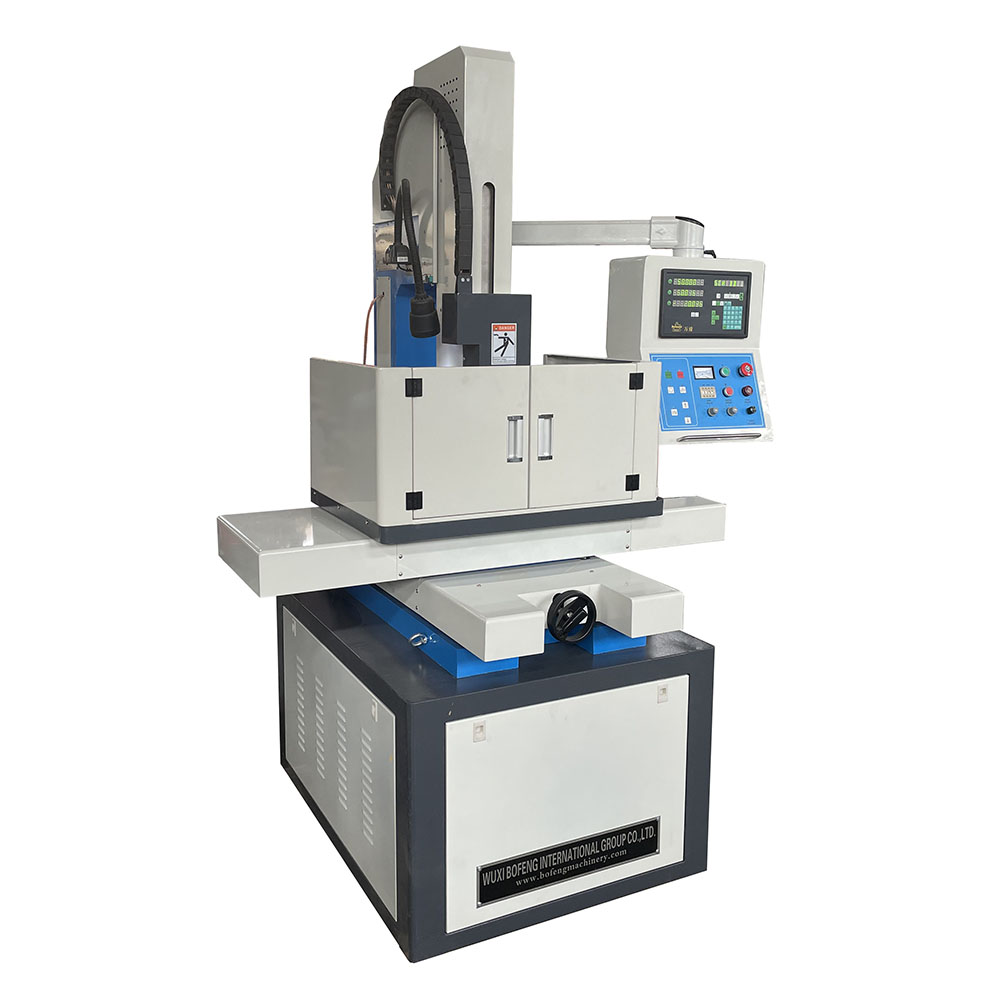

The high speed EDM drilling machine is a high-speed electric spark drilling machine, also called an electric spark punching machine. It is a special machine tool used for high-precision punching and drilling on metal workpieces. Compared with traditional drilling machines, high-speed EDM drilling machines can complete more precise hole processing in a shorter time and are especially suitable for processing high hardness, high viscosity and difficult-to-machine materials. Its working principle is to use electric spark discharge technology to form tiny discharge holes on the surface of the workpiece, and then expand the holes through high-speed rotating electrodes to finally form the required holes.

Advantages of high speed EDM drilling machine:

1. High speed EDM drilling machines can process materials with high hardness, high viscosity and difficult to process, such as tungsten steel, ceramics, metal alloys, etc. Traditional drilling machines tend to have low efficiency and poor accuracy when processing these materials, while high-speed EDM drilling machines can complete more precise hole processing in a shorter time, improving processing efficiency and accuracy.

2. High speed EDM drilling machine can process holes of various shapes and sizes, including deep holes and small holes. This is something that traditional drilling machines cannot achieve. High-speed EDM drilling machines can process holes of various shapes and sizes through different electrodes and processing parameters.

3. Mechanical stress and thermal stress will not be generated during processing, and will not cause deformation and cracks of the workpiece. This is another advantage. Traditional drilling machines need to apply force and generate heat during processing, which can easily cause deformation and cracks in the workpiece. However, the processing process of high speed EDM drilling machines is non-contact and does not produce mechanical stress or thermal stress, thus avoiding these problems.

4. The high speed EDM drilling machine can realize automated production and improve production efficiency and stability. High-speed EDM drilling machines can be used in conjunction with automated production lines to achieve automated production. In automated production lines, high-speed EDM drilling machines can achieve high-speed, high-precision, and continuous processing, improving production efficiency and stability.

5. The operation is simple and does not require complex operating skills and experience. It is easier to use than traditional drilling machines.

6. High speed EDM drilling machine can reduce processing costs, waste and losses. During the machining process, tools and coolant are not required, which reduces machining costs. At the same time, because the processing process is contactless, no waste and loss are generated, which also reduces costs.

7. The high-speed EDM drilling machine can achieve non-contact processing and will not pollute the environment or harm health. The processing process of the high-speed EDM drilling machine is contactless, does not produce dust and wastewater, does not pollute the environment or harm health, and meets environmental protection requirements.

Maintenance of high speed EDM drilling machine:

High speed EDM drilling machine is a high-precision drilling equipment capable of high-speed EDM drilling on hard materials. In order to ensure the stability and long-term use of the machine, it is very important to perform regular maintenance and upkeep. Maintenance and maintenance work includes checking the wear of electrical systems, hydraulic systems, cutting tools, electrodes and other components, cleaning work surfaces and guide rails, replacing filters and oil seals, checking cooling systems and gas lines, etc. In addition, when using the machine, you must also pay attention to operating specifications to prevent misoperation and machine failure. Through regular maintenance and upkeep, the stability and long-term use of the machine can be ensured, and production efficiency and product quality can be improved.