Contact us

- +86 13815922677 / +86-523-8549496

- +86-523-8549496

- joyce@arismachinery.com / joycechen2677@gmail.com

- No.999,Tianmu West Road,Jiangyan District,Taizhou,China

CNC turning machine controls the workpiece to be cut while rotating through the computer program. It can be used to process a variety of materials including metal, plastic, and wood. It can automatically complete complex processing tasks and improve production efficiency and precision. It is commonly used in the manufacture of parts, tools, and mechanical components, among others.

Application field of CNC turning machine:

Automobile manufacturing: It can be used to manufacture auto parts, such as wheel hubs, crankshafts, camshafts, drive shafts, etc.

Aerospace: It can be used to manufacture aerospace parts, such as engine parts, hydraulic system parts, aviation instruments, etc.

Electronics manufacturing: It can be used to manufacture electronic product components, such as mobile phones, computers, flat-screen TVs, etc.

Medical devices: These can be used to manufacture medical device components, such as artificial joints, dental equipment, surgical instruments, etc.

Machinery manufacturing: It can be used to manufacture various mechanical parts, such as bearings, gears, threads, nuts, etc.

Precision processing: It can be used for high-precision processing, such as optical components, molds, templates, etc.

Features of CNC turning machine:

High-precision: It has high-precision processing capabilities and can achieve micron-level processing accuracy.

High efficiency: With high-efficiency processing capability, high-speed processing and continuous processing can be realized to improve production efficiency.

Versatile: Multiple machining operations can be performed, such as turning, drilling, milling, tapping, etc.

The high degree of automation: It has the characteristics of a high degree of automation, and can realize functions such as automatic tool change, automatic measurement, and automatic deviation correction.

Good stability: It has the characteristics of good stability, which can ensure the stability and consistency of processing quality.

Strong adaptability: suitable for processing various materials, such as metal, plastic, wood, etc.

Shorten the processing cycle: C can realize fast tool change and automatic processing, which can shorten the processing cycle and improve production efficiency.

CNC turning machines can be classified into the following types:

1. Horizontal CNC turning machine: This type of machine has a horizontal spindle and is used for turning cylindrical parts.

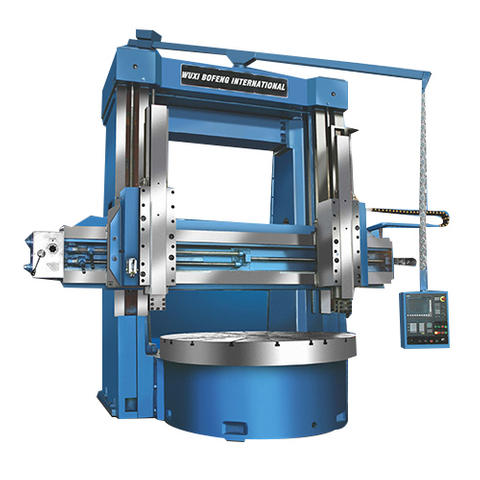

2. Vertical CNC turning machine: This type of machine has a vertical spindle and is used for turning large, heavy parts.

3. Swiss-type CNC turning machine: This type of machine is used for high-precision turning of small parts with complex geometries.

4. Multi-axis CNC turning machine: This type of machine has multiple axes of motion and is used for complex turning operations.

5. Gang tool CNC turning machine: This type of machine has multiple tools mounted on a single turret and is used for the high-volume production of small parts.

6. Turret CNC turning machine: This type of machine has a single turret with multiple tools and is used for medium-volume production of parts with moderate complexity.